Views: 98 Author: Jiawei Huang Publish Time: 2025-11-16 Origin: Site

Complete Guide to Zinc Coating: Principles, Methods, and Applications in Steel Fabrication

Zinc coating is one of the most widely used anti-corrosion treatments for steel components, commonly applied in automotive manufacturing, railway transportation, agricultural machinery, shipbuilding, and industrial equipment structures. As performance requirements for structural components continue to rise—particularly regarding lifespan, reliability, and surface quality—multiple zinc coating technologies have evolved, including hot-dip galvanizing, electro-galvanizing, cold galvanizing, sherardizing, mechanical plating, and thermal spray zinc.

This article systematically analyzes the protection mechanisms of zinc, the major zinc-coating processes, their characteristics, and respective application scenarios. It also discusses process selection from an engineering perspective for manufacturers with integrated capabilities such as laser cutting, robotic welding, CNC machining, and surface coating. The goal is to provide technical reference for structural design, process planning, and quality control.

When exposed to air, moisture, salt spray, or industrial pollutants, steel undergoes electrochemical corrosion, leading to surface degradation, reduced strength, and potential structural failure. According to NACE International (2016), global economic loss from corrosion accounts for 3–4% of the world’s GDP.

Therefore, applying a zinc coating to create a durable anti-corrosion barrier has become one of the most economical and effective protection methods for steel structures and mechanical components.

A zinc coating provides both barrier protection and galvanic (sacrificial) protection. As noted by the American Galvanizers Association (AGA), when zinc and steel are exposed simultaneously to an electrolyte, zinc corrodes preferentially, protecting the steel from oxidation.

With the development of intelligent manufacturing, structural component producers equipped with laser cutting, robotic welding, CNC machining, and automated coating lines are now able to achieve significantly improved consistency, fit-up quality, and surface appearance for zinc-coated products.

Zinc protects steel primarily through the following three mechanisms:

(1) Barrier Protection

The zinc layer forms a dense metallic barrier that blocks oxygen, moisture, chloride ions, and other corrosive media from reaching the steel substrate.

(2) Sacrificial Protection

According to the AGA (Zinc Coatings, 2020):

“Zinc corrodes preferentially to steel, providing galvanic protection even when small areas of the steel are exposed.”

Because zinc has a lower electrochemical potential than iron, it sacrifices itself first, thereby protecting the steel.

(3) Self-Healing Effect

When the coating is damaged, surrounding zinc can migrate and form basic zinc carbonate, covering the exposed area and slowing corrosion from spreading.

Below are the six primary zinc-coating methods widely used in industry.

Process:

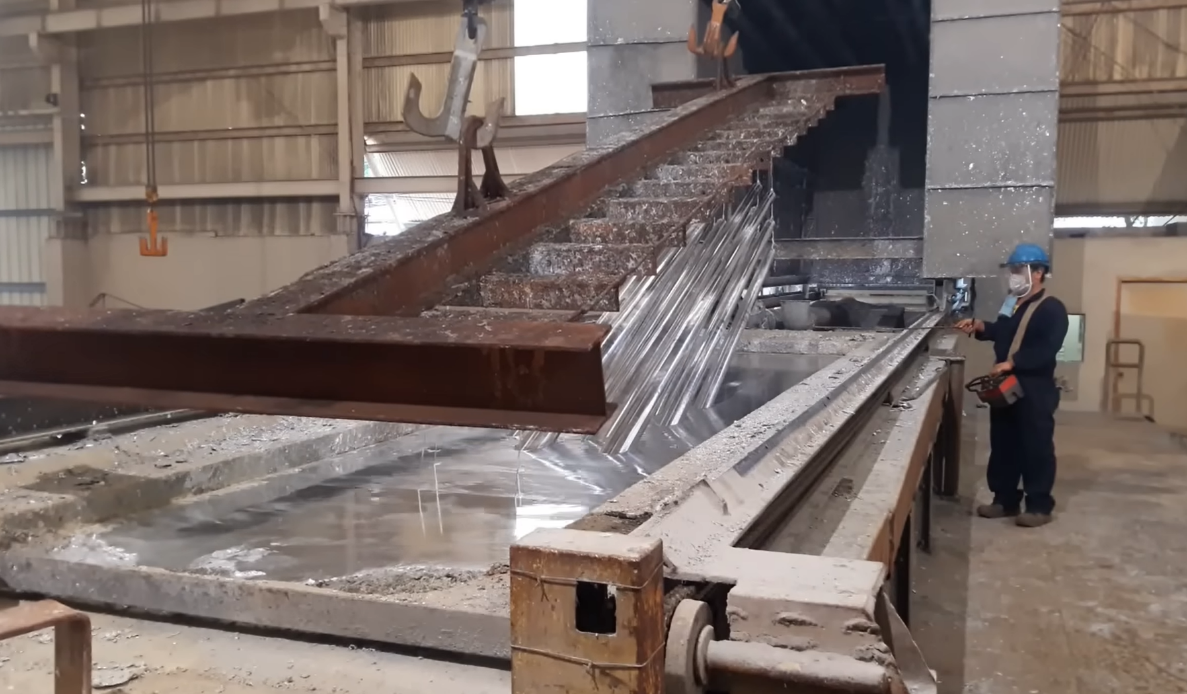

Cleaned steel components are immersed in molten zinc at approximately 450 °C, forming zinc-iron alloy layers and an outer pure zinc layer through metallurgical bonding.

Features:

• Thick zinc layer; strong adhesion and excellent durability

• Effective coverage on edges, corners, threads, and cavities

• Ideal for large structures and harsh environments

• Limited by zinc kettle size; higher cost

Recommended Videos:

• Hot-dip Galvanizing Full Process

https://www.youtube.com/watch?v=3Q9yH1XsLQY

• In-factory dipping demonstration

https://www.youtube.com/watch?v=Az87Q0JedG4

Applications:

Large steel structures, railway components, agricultural machinery frames, marine bases, outdoor equipment.

Process:

Zinc ions are electrodeposited onto the steel surface to form a thin, uniform coating.

Features:

•Smooth, bright appearance; excellent surface quality

• Thin zinc layer; weaker corrosion resistance than hot-dip

• Lower cost; ideal for light-corrosion environments

Recommended Videos:

• What Is Electro-galvanizing? Full Explanation

https://www.youtube.com/watch?v=yi30Iqxu2pE

• Electro-galvanizing of metal hardware (factory process)

https://www.youtube.com/watch?v=raYQuAItegM

Applications:

Appliance housings, automotive panels, electronic enclosures, small structural parts.

For your company: highly suitable for control cabinets, thin-plate brackets, and internal structural components.

Process:

Zinc-rich paint containing high-purity zinc powder is sprayed or brushed onto steel to form a protective coating.

Features:

• A coating-based method; flexible and suitable for on-site work

• Best for maintenance and touch-up

• Shorter lifespan than metallurgical coatings

Applications:

Repairs, oversized structures, on-site work environments.

Process:

Steel components are tumbled with zinc powder at 360–400 °C, allowing solid-state diffusion to form a zinc-iron alloy layer.

Features:

• Strong metallurgical bond; no hydrogen embrittlement

• Gray, matte appearance

Applications:

High-strength fasteners, nuts, bolts, small complex parts.

Process:

Zinc powder adheres to the steel surface under mechanical impact from tumbling with glass beads or similar media.

Features:

• No hydrogen embrittlement

• Uniform zinc layer, though weaker adhesion than metallurgical processes

Applications:

Nuts, washers, small hardware components.

Process:

Zinc is melted using a flame or electric arc and sprayed onto steel surfaces to form a thick coating.

Features:

• Very thick zinc layer; suitable for large structures

• Can be applied on-site

• Often combined with top coatings for extended protection

Applications:

Bridges, large machinery, marine structures, heavy equipment.

Process | Zinc Layer Thickness | Corrosion Resistance | Appearance | Cost | Suitable for Large Parts | |

Hot-dip Galvanizing | ★★★★★ | ★★★★★ | ★★ | Medium | ★★★★★ | |

Electro-galvanizing | ★★ | ★★ | ★★★★★ | Low | ★★ | |

Cold Galvanizing | ★★ | ★★ | ★★ | Low | ★★ | |

Sherardizing | ★★★ | ★★★★ | ★★ | Medium | ★★ | |

Mechanical Plating | ★★ | ★★ | ★★ | Low | ★★ | |

Thermal Spray Zinc | ★★★★ | ★★★★ | ★★ | Medium | ★★★★★ |

(1) Zinc Thickness – The Most Critical Factor

According to the AGA:

“Coating life is directly proportional to zinc thickness.”

(2) Service Environment

• Coastal & industrial environments → significantly reduced lifespan

• Indoor environments → minimal corrosion

(3) Surface Preparation Quality

• Degreasing, pickling, and activation directly affect adhesion

• Robotic welding provides consistent welds, producing cleaner surfaces and fewer post-galvanizing defects

(4) Steel Chemistry

Silicon and phosphorus levels affect hot-dip galvanizing thickness and uniformity.

Your company possesses the following capabilities, which strongly support zinc-coating quality:

• Laser cutting → clean edges, reduced burrs, improved adhesion

• Robotic welding → consistent seams, fewer coatings defects

• CNC machining → precision on key features, stable dimensions after galvanizing

• Spray coating line → enables “Duplex Coating” (galvanizing + topcoat) for extended protection

Ideal component categories for zinc coating:

Machine bases, steel frames, railway components, marine supports, agricultural equipment frames, industrial enclosures.

Automotive Industry

Extensive use of electro-galvanized steel sheets (EG) for improved corrosion resistance.

Railway Transportation

Hot-dip galvanized chassis and support components ensure 20–40 years of service life.

Agricultural Machinery

Zinc-coated structures withstand mud, fertilizer, and moisture.

Marine Engineering & Shipbuilding

Hot-dip + thermal spray combinations widely applied to marine load structures.

Zinc coating is one of the most mature, cost-effective, and reliable corrosion protection methods for steel materials, suitable for components ranging from precision hardware to large steel structures. For manufacturers equipped with laser cutting, robotic welding, CNC machining, and coating systems, combining hot-dip galvanizing, electro-galvanizing, and thermal spray zinc enables comprehensive protection in environments ranging from indoor applications to severe corrosion conditions.

• American Galvanizers Association. Zinc Coatings: Characteristics and Applications. AGA, 2020.

• Court Galvanizing Inc. Technical Guide to Zinc Coatings.

• ScienceDirect. Electro-galvanization of zinc-nickel alloy onto mild steel, 2022.

• GAA Australia. Types of Galvanizing and Zinc Coatings.

• NACE International. International Measures of Corrosion Costs, 2016.