Views: 355 Author: Jiawei Huang Publish Time: 2025-10-28 Origin: https://www.weldingframes.com/

Cutting square tubes (i.e., square tube materials) requires selecting an appropriate method based on the material, thickness, precision requirements, and processing volume. The core cutting methods are mainly divided into two categories: mechanical cutting (cold cutting) and thermal cutting. Below is a comprehensive and practical cutting solution covering detailed explanations of cutting methods, comparative selection, and operational precautions.

Mechanical cutting separates square tubes through physical force. During the cutting process, there is no significant thermal deformation of the material, and the cutting surface has high flatness. It is suitable for scenarios requiring strict precision. There are three main types: saw blade cutting (including semi-automatic sawing machines), manual saw blade cutting, and punching/shearing.

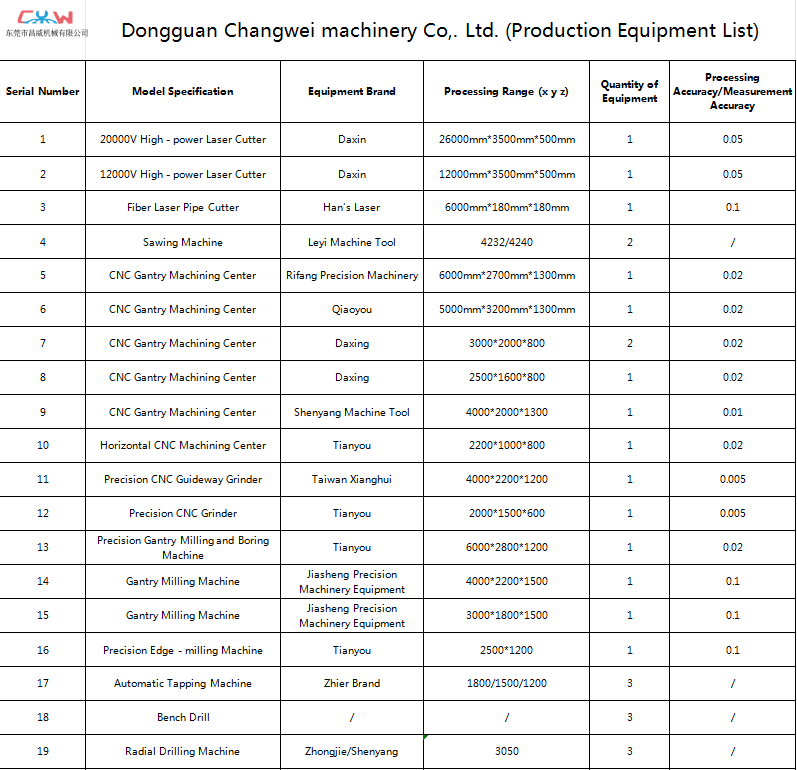

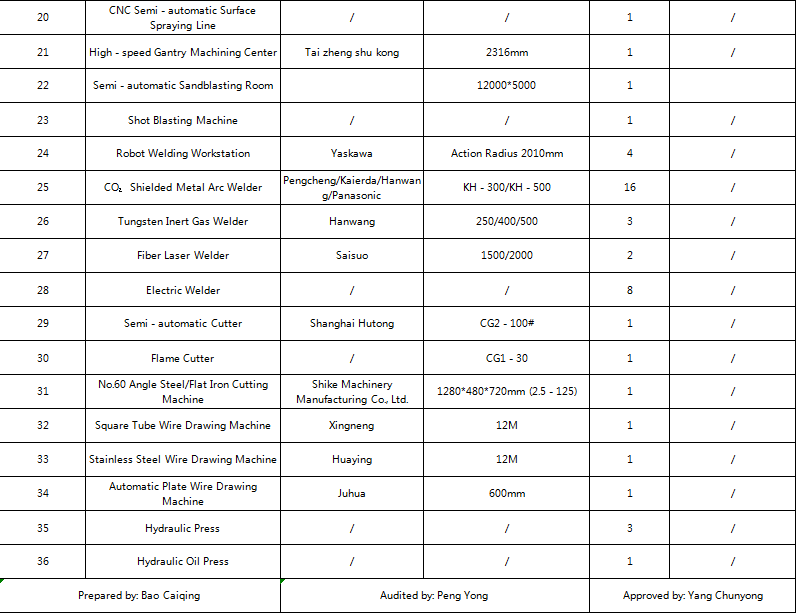

Company Overview of China Manufacturer - Dongguan Changwei Machinery Co., Ltd. (made-in-china.com)

Equipment Type: Semi-automatic sawing machines (equipped with automatic feeding, positioning, and cutting systems; manual assistance required only for material loading and unloading)

Working Principle: The alloy saw blade rotates at high speed (usually 3000-5000 rpm). The machine automatically positions the square tube according to the preset length, and the saw blade feeds stably to cut the tube. A built-in cooling system sprays cutting fluid continuously to reduce saw blade wear and burrs on the cutting surface.

Core Parameters:

l Applicable Materials: Carbon steel, stainless steel, aluminum alloy square tubes

l Applicable Thickness: 3-25 mm (medium-thin to medium thickness)

l Cutting Precision: Length error ±0.1-0.2 mm, cutting surface perpendicularity ≤0.08 mm/m

l Efficiency: Cutting speed of 10 mm thick carbon steel is approximately 220 mm/min; can process 50-100 pieces per hour (depending on tube length)

Operational Points:

l Saw Blade Matching: Use cobalt-containing cemented carbide saw blades (36-48 teeth) for stainless steel to resist wear; use anti-slip serrated saw blades (60-80 teeth) for aluminum alloys to prevent material slipping; use ordinary cemented carbide saw blades for carbon steel.

l Parameter Setting: Adjust the feeding speed (50-150 mm/min) according to the material thickness—slower speed for thick tubes (≥20 mm) to ensure cutting stability, faster speed for thin tubes (3-10 mm) to improve efficiency.

l Cooling Maintenance: Check the cutting fluid level before operation; replace the fluid every 2-3 months (use metal-specific cutting fluid: extreme pressure type for stainless steel, anti-corrosion type for aluminum alloys) to avoid saw blade overheating and tooth chipping.

Applicable Scenarios: Medium-batch processing of square tubes with stable precision requirements, such as industrial equipment brackets, mechanical structural parts, and standardized frame components.

Equipment Type: Manual cutting machines (portable or desktop, with manual feeding and positioning)

Working Principle: The operator adjusts the positioning baffle to set the cutting length, clamps the square tube manually, and pushes the saw blade holder to make the high-speed rotating saw blade cut through the tube. A manual valve controls the cooling fluid spray.

Core Parameters:

l Applicable Materials: Carbon steel, stainless steel, aluminum alloy square tubes

l Applicable Thickness: 3-15 mm (thin to medium-thin thickness)

l Cutting Precision: Length error ±0.2-0.4 mm (depends on operator skill), cutting surface perpendicularity ≤0.12 mm/m

l Efficiency: Cutting speed of 10 mm thick carbon steel is approximately 150 mm/min; can process 20-40 pieces per hour

Operational Points:

l Positioning Check: After setting the baffle, test-cut 1-2 pieces first to verify the length accuracy; adjust the baffle in time if there is a deviation.

l Feeding Control: Push the saw blade evenly during cutting—avoid excessive force that may cause saw blade deflection, or too little force that leads to slow cutting and saw blade overheating.

Applicable Scenarios: Small-batch, flexible processing scenarios, such as on-site maintenance, sample production, and small-scale customization of square tubes.

3. Punching/Shearing: High-Efficiency Method for Large-Batch Thin-Walled Parts

Equipment Type: Punching machines (with special square tube molds), hydraulic shearing machines (equipped with square tube fixtures)

Working Principle: Through the instantaneous punching force (usually 5-50 tons) of the mold edge or shear blade, the square tube is broken and separated at the preset position.

Core Parameters:

l Applicable Materials: Carbon steel, aluminum alloy (thin-walled only)

l Applicable Thickness: ≤3 mm (ultra-thin wall)

l Cutting Precision: Length error ±0.3-0.5 mm, slight deformation may occur on the cutting surface (≤0.1 mm)

l Efficiency: Processing time per piece ≤1 second (high efficiency, suitable for large batches)

Operational Points:

l Mold Adaptation: Customize molds according to the cross-sectional size of the square tube (e.g., 20×20 mm, 30×30 mm) to avoid dimensional deviations.

l Burr Treatment: After cutting, use a file or sanding belt machine to remove burrs on the cutting surface to prevent scratches during subsequent assembly.

Applicable Scenarios: Standardized large-batch thin-walled parts, such as guardrail poles, simple frames, and decorative thin-walled square tubes.

Deformation Control Thermal cutting uses high-temperature energy (above 20000°C) to melt or vaporize the local area of the square tube for separation. It is suitable for thick-walled pipes but will produce a heat-affected zone (the smallest for laser cutting). Selection should be based on material and precision requirements. There are three main types: plasma cutting, flame cutting, and laser cutting.

Equipment Type: Air plasma cutting machines (for carbon steel), inert gas plasma cutting machines (for stainless steel/aluminum)

Working Principle: The plasma arc generates a high temperature of 20000-30000°C to melt the cutting area of the square tube. At the same time, high-speed gas flow (air, argon, nitrogen) blows away the molten slag to form a cut.

Core Parameters:

l Applicable Materials: Carbon steel, stainless steel, aluminum alloy, copper alloy (multiple metals)

l Applicable Thickness: 5-80 mm (thick-walled) Cutting Precision: Length error ±0.3-0.5 mm, cutting surface roughness Ra 12.5-25 μm

l Efficiency: Cutting speed of 20 mm thick carbon steel is approximately 100 mm/min

Operational Points:

l Gas Selection: Use compressed air (low cost) for carbon steel, and a mixture of argon and hydrogen (anti-oxidation) for stainless steel/aluminum.

l Heat-Affected Zone Control: Control the cutting speed at 80-120 mm/min to avoid excessive expansion of the heataffected zone (>2 mm) due to too slow speed.

Applicable Scenarios: Cutting of thick-walled multi-metal parts, such as heavy machinery structural parts, thick-walled pipe connectors, and stainless steel thick-walled frames.

Equipment Type: Oxy-acetylene flame cutting machines (manual/semi-automatic)

Working Principle: The oxy-acetylene flame (temperature approximately 3100°C) preheats the square tube to its ignition point (800-900°C for lowcarbon steel). Then, high-pressure oxygen (pressure 0.5-0.8 MPa) is introduced to make the metal burn, and the molten slag is blown away to form a cut.

Core Parameters:

l Applicable Materials: Only low-carbon steel and low-alloy steel (stainless steel/aluminum cannot burn and are not applicable)

l Applicable Thickness: 20-200 mm (extra-thick wall)

l Cutting Precision: Length error ±0.5-1 mm, cutting surface roughness Ra 25-50 μm (prone to iron oxide slag)

l Efficiency: Cutting speed of 50 mm thick carbon steel is approximately 30 mm/min (low efficiency)

Operational Points:

l Preheating Control: The preheating temperature must reach the ignition point to avoid uneven cuts due to insufficient preheating.

l Slag Cleaning: After cutting, use hammering or high-pressure water guns to remove iron oxide slag from the cutting surface to prevent impact on subsequent welding.

Applicable Scenarios: Rough processing of extra-thick-walled carbon steel, such as large steel structure bases, heavy equipment supports, and thick-walled parts with low precision requirements.

Carbon Steel Welded Components, CNC Maching products from China Manufacturers - Dongguan Changwei Machinery Co., Ltd. - page 1. (made-in-china.com)

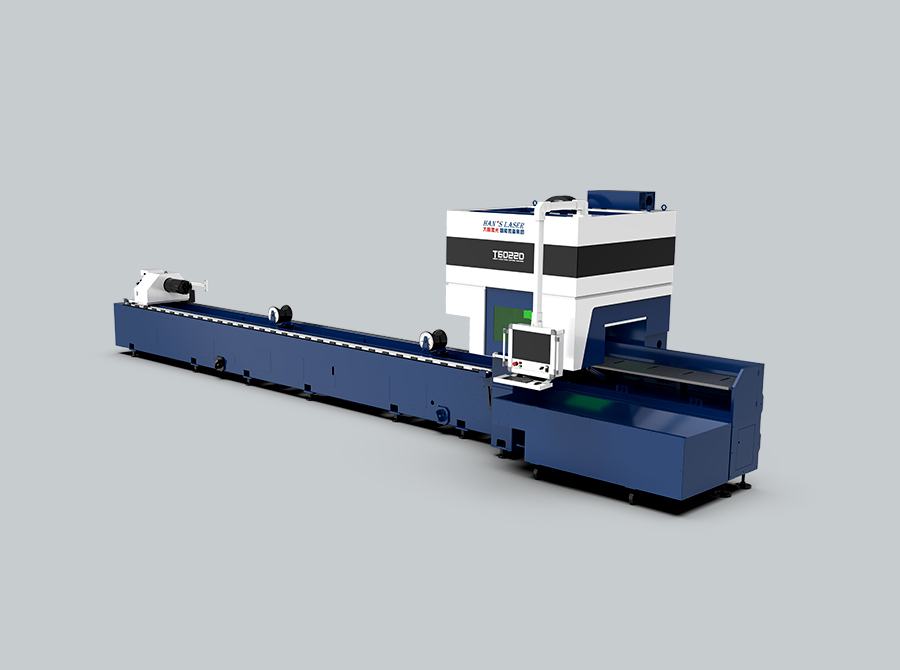

Equipment Type: Fiber laser cutting machines (for metals), CO₂ laser cutting machines (for non-metals/thin metals)

Working Principle: A high-energy-density laser beam (power density 10⁶-10⁸ W/cm²) irradiates the square tube, instantly melting or vaporizing the material. With the assistance of auxiliary gas (oxygen for carbon steel, nitrogen for stainless steel) to blow away the molten slag, high-precision cutting is achieved.

Core Parameters:

l Applicable Materials: Metals (carbon steel, stainless steel, aluminum), non-metals (plastic, wood, acrylic)

l Applicable Thickness: ≤30 mm for metals, ≤50 mm for non-metals (medium-thick wall)

l Cutting Precision: Length error ≤±0.1 mm, cutting surface roughness Ra 3.26.3 μm (no burrs) Efficiency: Cutting speed of 10 mm thick carbon steel is approximately 80 mm/min

Operational Points:

l Focus Adjustment: Adjust the laser focus position according to the thickness (offset downward for thick walls, centered for thin walls) to ensure the perpendicularity of the cut.

l Auxiliary Gas: Use nitrogen for stainless steel (anti-oxidation, bright white cutting surface) and oxygen for carbon steel (improving efficiency, slight oxidation on the cutting surface).

Applicable Scenarios: Cutting of high-precision complex parts, such as precision equipment casings, special-shaped structural parts, and decorative parts with high appearance requirements.

1. Core Parameter Comparison Table

Cutting Method | Applicable Materials | Applicable Thickness | Cutting Precision (Length Error) | Cutting Surface Roughness (Ra) | Efficiency (10 mm Thick Carbon Steel) | Equipment Cost | Heat-Affected Zone Width |

Semi-Automatic Sawing Cutting | Steel, Aluminum, Stainless Steel | 3-25 mm | ±0.1-0.2 mm | 6.3-10 μm | Approximately 220 mm/min | Medium | None |

Manual Saw Blade Cutting | Steel, Aluminum, Stainless Steel | 3-15 mm | ±0.2-0.4 mm | 8-12.5 μm | Approximately 150 mm/min | Low | None |

Punching/Shearing | Steel, Aluminum (ThinWalled) | ≤3 mm | ±0.3-0.5 mm | 12.5-25 μm | ≤1 second per piece | Low | None |

Plasma Cutting | Steel, Stainless Steel, Aluminum, Copper | 5-80 mm | ±0.3-0.5 mm | 12.5-25 μm | Approximately 100 mm/min | Medium | 0.5-2 mm |

Flame Cutting | LowCarbon Steel, LowAlloy Steel | 20-200 mm | ±0.5-1 mm | 25-50 μm | Approximately 30 mm/min | Low | 2-5 mm |

Laser Cutting | Metals/NonMetals | ≤30 mm (Metals) | ≤±0.1 mm | 3.2-6.3 μm | Approximately 80 mm/min | High | ≤0.1 mm |

2. Scenario-Based Selection Recommendations

1. Medium-Batch + Stable Precision (e.g., industrial brackets, mechanical parts): Prioritize semi-automatic sawing machine cutting—balances efficiency and precision, with controllable cost.

2. Small-Batch + Flexibility (e.g., on-site maintenance, samples): Choose manual saw blade cutting—low equipment investment, easy to operate.

3. Thick-Walled + Multi-Metal Requirements (e.g., stainless steel thick-walled parts, aluminum thick-walled parts): Select plasma cutting (5-80 mm) for wide material adaptability.

4. Extra-Thick-Walled Carbon Steel + Low-Cost (e.g., heavy structural parts): Choose flame cutting (20-200 mm) for economical thick-walled processing.

5. Large-Batch Thin-Walled + High-Efficiency (e.g., guardrails, light shelves): Choose punching/shearing (≤3 mm) for ultra-fast batch production.

6. High Precision + Complex Shapes (e.g., precision casings, appearance parts): Select laser cutting for error-free precision and smooth surfaces.

1. Safety Protection (Top Priority)

l Thermal Cutting Protection: Wear arc-proof goggles (shade number 10-12) to resist strong light; wear flame-retardant cotton protective clothing and high-temperature-resistant gloves to prevent molten slag scalds. Lay a fire blanket under the workbench and keep a fire extinguisher nearby.

l Mechanical Cutting Protection: For semi-automatic/manual sawing machines, wear impact-resistant goggles to prevent saw blade debris splashing; do not wear loose clothing or gloves (avoid entanglement with rotating parts). Keep hands at least 15 cm away from the saw blade during operation.

2. Material Fixing and Positioning

l Semi-Automatic Sawing Machine: Use the machine’s built-in pneumatic clamp to fix the square tube—ensure the clamp pressure is 0.4-0.6 MPa (too low will cause tube displacement, too high will deform thin tubes). Check the positioning baffle’s tightness weekly to avoid looseness-induced errors.

l Manual Cutting: Use a vice or V-shaped fixture to clamp the tube; place a rubber pad between the fixture and the tube for thin-walled materials (≤5 mm) to prevent surface scratches.

3. Cooling and Thermal Deformation Control

l Mechanical Cutting Cooling: Semi-automatic sawing machines must ensure the cooling fluid flow rate is ≥8 L/min; for manual cutting, press the cooling valve continuously during cutting (do not interrupt, otherwise the saw blade will overheat).

l Thermal Cutting Cooling: After plasma/flame cutting, cool thick-walled tubes (≥20 mm) with air (avoid water cooling, which causes thermal stress cracking); cool thin-walled tubes (≤10 mm) with low-pressure water mist to reduce deformation.

4. Post-Processing

l Burr Removal: For semi-automatic sawing machine cuts, use a file or deburring tool to polish the edge (1-2 minutes per piece); for thermal cutting, use an angle grinder with a 120-mesh grinding wheel to smooth the surface.

l Rust Prevention: Spray anti-rust paint on carbon steel cuts within 24 hours; wipe stainless steel/aluminum cuts with alcohol to remove oil stains (no rust prevention needed for these materials).

l Precision Inspection: Use a digital caliper (precision 0.01 mm) to check the length of key parts; use a square to verify the cutting surface perpendicularity (error must be ≤0.1 mm/m).

1. Fully Automatic Laser Cutting Machine: Fiber laser type with a cutting precision of ±0.1 mm. It supports programming cutting of special-shaped parts and is suitable for metal/non-metal square tubes, making it ideal for high-precision and complex shape processing.

2. Semi-Automatic Sawing Machine: Equipped with special alloy saw blades, it has a cutting efficiency of 200 mm/min and supports batch processing of medium-thin wall square tubes (3-20 mm) with controllable costs.

If you have specific requirements for materials (such as carbon steel, 304 stainless steel, 6061 aluminum alloy, or other material pipes), thickness, or precision, please feel free to send an email for consultation. We will provide a customized cutting solution!